Stuffing Box Assembly Drawing Pdf Free

Stuffing Box ArrangementIn most of the pumps, and even in the shaft, the stuffing box consists of a stack of packing rings or a short square cross sectional rope made of greased flax. The material is closely packed or wound tightly around the propeller or pump shaft with threaded nut or spacer compressing it in place. There are also hose clamps attached to the stuffing box, which are then attached to a short piece of heavy duty rubber hose. The rubber hose is clamped around the place where the propeller opens in the ship’s hull.Stuffing box is also seen in steam engines, at the place where the reciprocates with the, which helps in preventing leakage of steam from the cylinder.In diesel engines, stuffing box is found in the bore for the piston rod in the bottom of the scavenge air box. The stuffing box prevents the entry of from the crankcase into the space. It also prevents the leaking of air from scavenge space to the crankcase.

Construction of a Diesel Engine Stuffing BoxThe whole arrangement is distributed into two parts, put together by a flanged joint. The housing generally consists of five ring grooves of which, the two uppermost grooves accommodate sealing rings to prevent blowing down of scavenge air along the piston rod. The bottom groves are fitted with scrapper rings in order to scrap the lubricating oil on the piston rod. The oil enters and leaves the housing through bores.

The two sealing rings are generally made of brass while the scrapper rings are made of steel.In between the two types of rings, a cofferdam attached with connecting pipes and bores is provided, which communicates with a control clock fitted on the engine. It is used to monitor the performance of sealing and scrapper rings Special FeaturesAll the stuffing boxes packed with flax rings are specifically fitted to allow a bit of leakage. The sealing is adjusted to receive a few drops of fluid per minute to maintain lubrication and subside the heat generated due to continuous motion of the shaft. This amount of water is not considered leakage and seldom creates a problem.

Stuffing Box Assembly Drawing Pdf Free Online

Few other types of sealing arrangements such as mechanical face seal and lip seal use materials or lubrication systems which are more technically advanced. There are also drip-less seals made of Teflon or carbon. Image Creditshttps://www.hnsa.org/doc/machinist/img/fig139.jpghttps://www.alohaowners.com/pages/projects/stuffing/stuffingbox.htm.

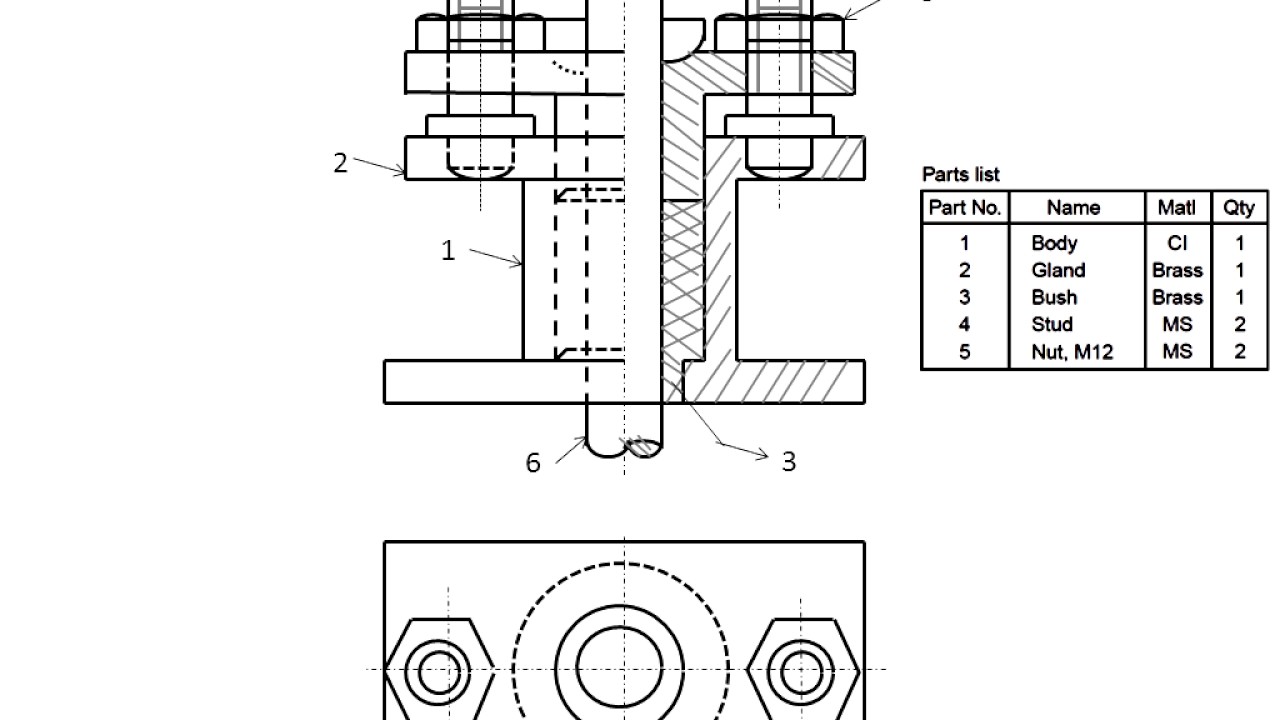

Assembly and Details machine drawing pdf.1.CHAPTER - 06 ASSEMBLY AND DETAILS DRAWING.A STEPS TO DRAW ASSEMBLY DRAWING FROM DETAILS DRAWING:-1. Understand the purpose, principle of operation and field of application of the given machine.This will help in understanding the functional requirements of individual parts and theirlocation.2. Examine thoroughly, the external and internal features of the individual parts.3. Choose a proper scale for the assembly drawing.4. Estimate the overall dimensions of the views of the assembly drawing and make the outlineblocks for each of the required view, leaving enough space between them, for indicatingdimensions and adding required notes.5. Draw the axes of symmetry for all the views of the assembly drawing.6. Begin with the view from the front, by drawing first, the main parts of the machine and thenadding the rest of the parts, in the sequence of assembly.7.

Project the other required views from the view from the front complete views.8. Mark the location and overall dimensions and add the part numbers on the drawing.9. Prepare the parts list.B STEPS TO DRAW PART OR DETAILS DRAWING FROM ASSEMBLYDRAWING:-1. Understand the assembly drawing thoroughly, by referring to the parts list and the differentorthographic views of the unit.2. Study the functional aspect of the unit as a whole. This will enable to understand thearrangement of the parts.3.

Visualize the size and shape of the individual components.4. As far as possible, choose full scale for the drawing. Small parts and complicated shapes mayrequire the use of enlarged scales so that their presentation will have a balanced appearance.5.

Select the minimum number of views required for describing each part completely. The viewfrom the front selected must provide maximum information of the part.6. The under mentioned sequence may be followed for preparing different views of each part:(i) Draw the main centre lines and make outline blocks, using the overall dimensions of theviews.(ii) Draw the main circles and arcs of the circles.(iii) Draw the main outlines and add all the internal features.(iv) Cross-hatch the sectional views.(v) Draw the dimension lines and add dimensions and notes.7. Check the dimensions of the mating parts.8.