Chopper Frame Blueprints Pdf Reader

Etsy uses cookies and similar technologies to give you a better experience, enabling things like:. basic site functions. ensuring secure, safe transactions. secure account login. remembering account, browser, and regional preferences.

remembering privacy and security settings. analysing site traffic and usage. personalized search, content, and recommendations.

helping sellers understand their audience. showing relevant, targeted ads on and off EtsyDetailed information can be found in Etsy’s and our. Personalized AdvertisingThese technologies are used for things like:. personalized ads. to limit how many times you see an ad. to understand usage via Google Analytics. to understand how you got to Etsy.

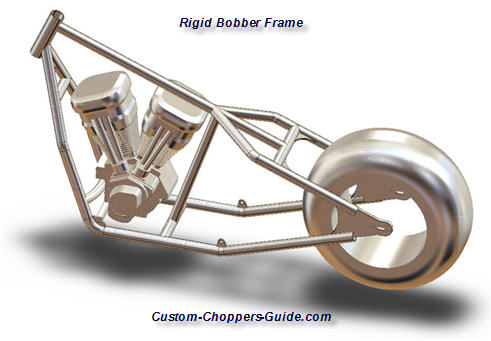

to ensure that sellers understand their audience and can provide relevant adsWe do this with social media, marketing, and analytics partners (who may have their own information they’ve collected). Saying no will not stop you from seeing Etsy ads, but it may make them less relevant or more repetitive. Find out more in our. Rigid Frame Jig BlueprintsBuilding your own ol' skool, 200, 230, 240, 250, 260, 280, 300 or 330 WIDE TIRE monster chopper?

A Frame Welding Jig is a MUST when building your dream bike!A top quality, fully adjustable Jig is the ONLY way to insure that your frame is straight, all the components are at the right angle and in position! And this set of blueprints will give you that jig.Building the Welding Jig from our Professional Custom Chopper Rigid Frame Welding Jig Blueprints is a MUST if you want a professional quality frame time after time. With this set of prints you will construct a top quality FULLY ADJUSTABLE Welding Jig. Tubing diameters are easy adjusted from 1.25, 1.375 and 1.5. No matter your style or design this jig will adjust to fit your needs. Long, short, low or tall all fit in this jig. Virtually any rake and stretch combination you can think of can be built.

All detailed views clearly display motor and transmission mount locations and other critical dimensions of frame components. Including forward control mounts and axle plates.These crisp and clear Working prints are the real thing, each is an original print - no fuzzy 'copies' here. Each set measure 36' x 97” (3 feet by 8 feet) and is printed on brilliant white paper strong enough to withstand shop notes yet attractive enough to display in a frame.

Prints are delivered in sturdy storage tube, no fold marks!These clear and easy to read, extremely accurate, LARGE 1/2 SCALE prints display BOTH Fraction and Decimal measurements of every critical dimensions and angle imaginable, including standard V-Twin engine, transmission, forward control and axle locations. These sets of plans give you ALL the dimensions and angles you will need to build your own Welding Jig including Basic Material Schedule and Builder Notes. These are the exact same dimensions as those used by all of the big bike manufactures.The process of building a bike can be frustrating to say the least. If you are considering building your own custom chopper these clear and precise prints are a must have. The more good information you acquire, the better prepared you are for success.

Now you KNOW what you are talking about!This original, complete and comprehensive set of detailed drawings is offered ONLY from BCC Orlando - accept NO OTHERS.

These plans are freely available from Crime Scene Choppers, they outline the construction of our frame jig as shown in Ron Covell's new 'Building a Chopper Chassis' video. Few of the dimensions or material callouts are critical. The width of part #6, the frame rail fixture, is determined by the ou tside width of your lower frame rails. Typically, the inside width is 8 3/8', so the outside width is 8.375 + 2.

Blueprint Reader Jobs

the diamater of your frame tubing. Check the alignment of your parts carefully as you work, a warped jig is worse than no jig at all!

7 8 6 5 4 4 6 5 4 3 3 3 3 3 1 2 1 2 ITEM NO. D E S C R I P T I O N L E N G T H 1 2 T U B E, R E C T A N G U L A R 3. 1 3 9 6 2 2 B A R S T O C K, R E C T A N G U L A R. 5 x 2 F l a t B a r 9 6 3 5 T U B E, R E C T A N G U L A R 3.

1 3 6 4 2 T U B E, R E C T A N G U L A R 3. 1 3 2 3 5 2 T U B E, S Q U A R E 2. 1 3 1 0 6 2 B A R S T O C K, R E C T A N G U L A R 0. 2 5 x 2 f l a t b a r 3 7 1 T U B E, R E C T A N G U L A R 3.

1 3 2 4 8 1 T U B E, R E C T A N G U L A R 3. 1 7 9 10 5 3 8 8 6 1 3 2 1/2' thick plate, 6' wide x 7' long with 2' x 3' rect. Hole in center 6.000 7.000.750.750.500 Stitch weld 2' x.5' flat bar to 2' x 3' tube then set up in mill and machine a 1/2' slot for the length of the tube. P A R T N U M B E R D E S C R I P T I O N Q T Y. 1 N e c k F i x t u r e 1 2 S l i d e r M e c h a n i s m 1 3 B o l t P l a t e 1 4 H H N U T 0.

5 0 0 0 - 1 3 - D - N 1/2'-13 nut welded to top of #3 1 5 P i v o t P l a t e 1.75' x 1.75' square bar stock 2 6 N e c k P i v o t 1 7 a l l t h r e a d 3 / 4 ' - 1 6 t h r e a d e d r o d 1 8 N e c k C o n e 45 degree cone to hold steering neck 2 9 D K A - 1 3 R e i d T o o l 1 1 0 S D K A - 1 3 R e i d T o o l 1 I T E M N O. D E S C R I P T I O N L E N G T H 1 1 T U B E, R E C T A N G U L A R 2 x 3 x. 5 2 1 B A R S T O C K, R E C T A N G U L A R.

Softail Frame Plans

5 x 2 F l a t B a r 2 6.